Your basket is currently empty!

Efficient and Durable

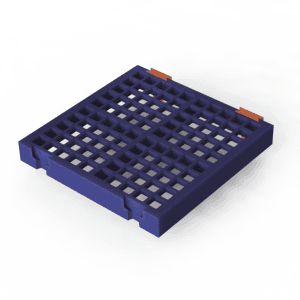

Polyurethane Screen Panels

Screening efficiency for your minerals

Our Panels

Polyurethane Screen Panels

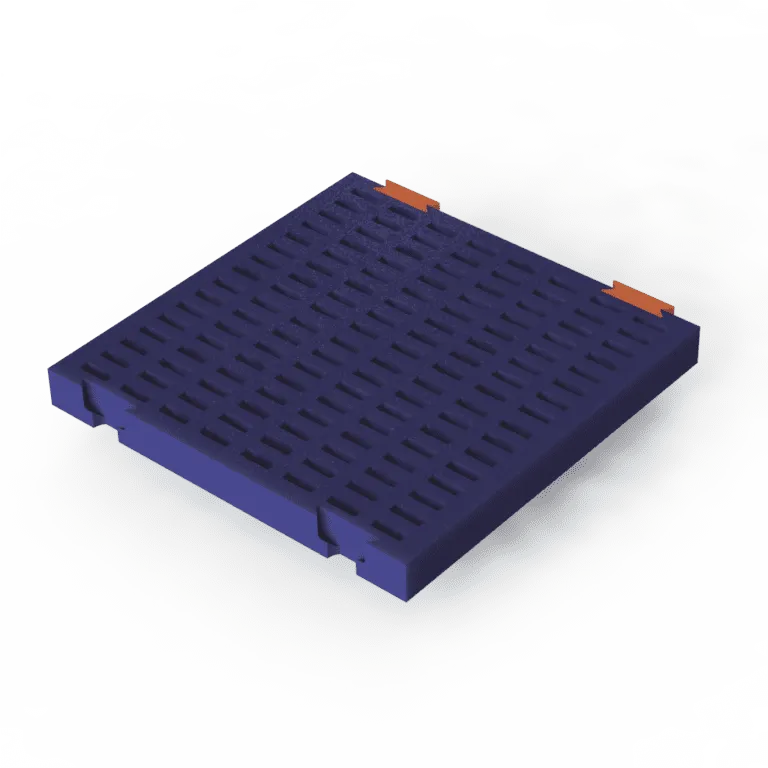

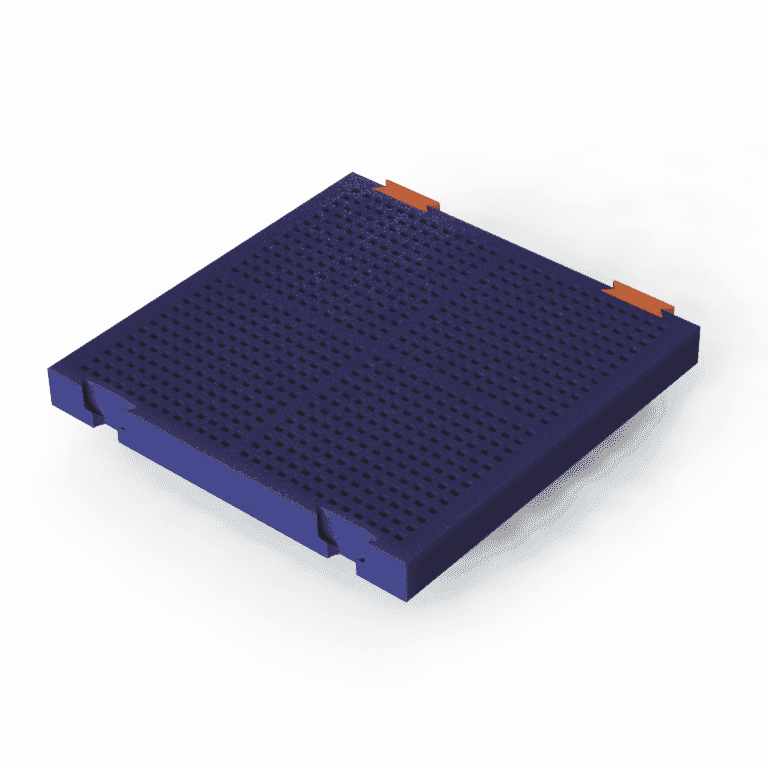

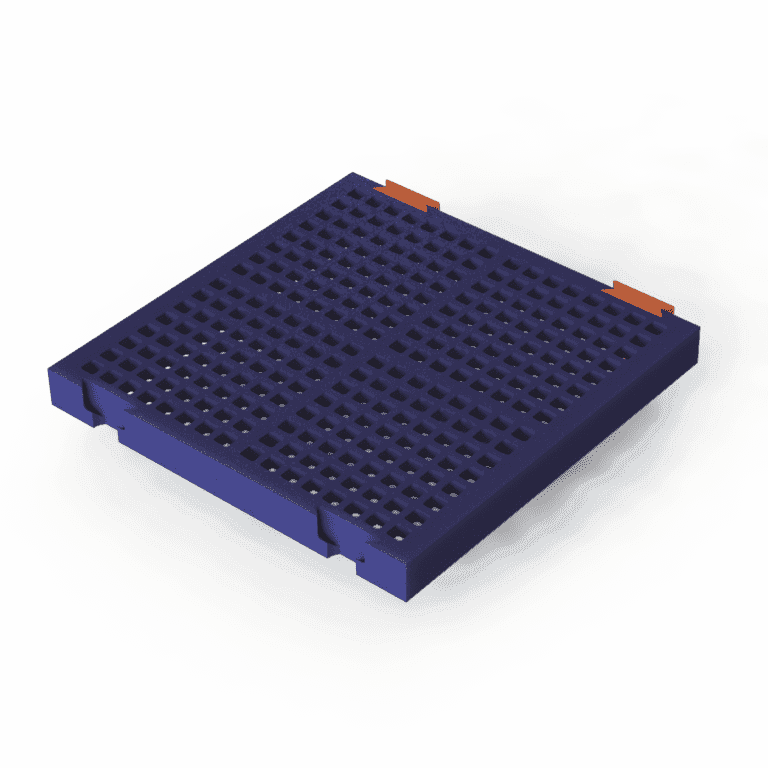

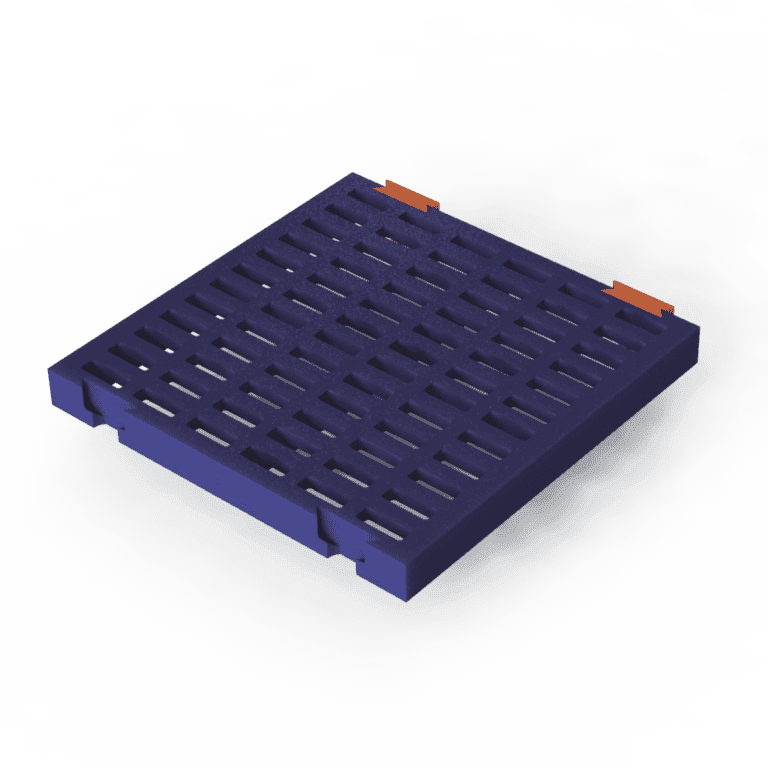

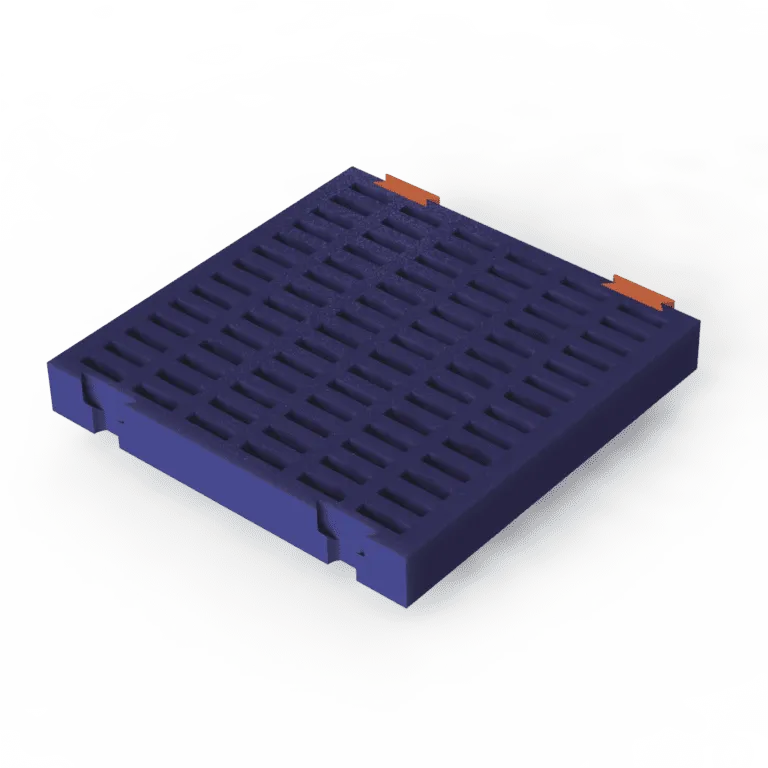

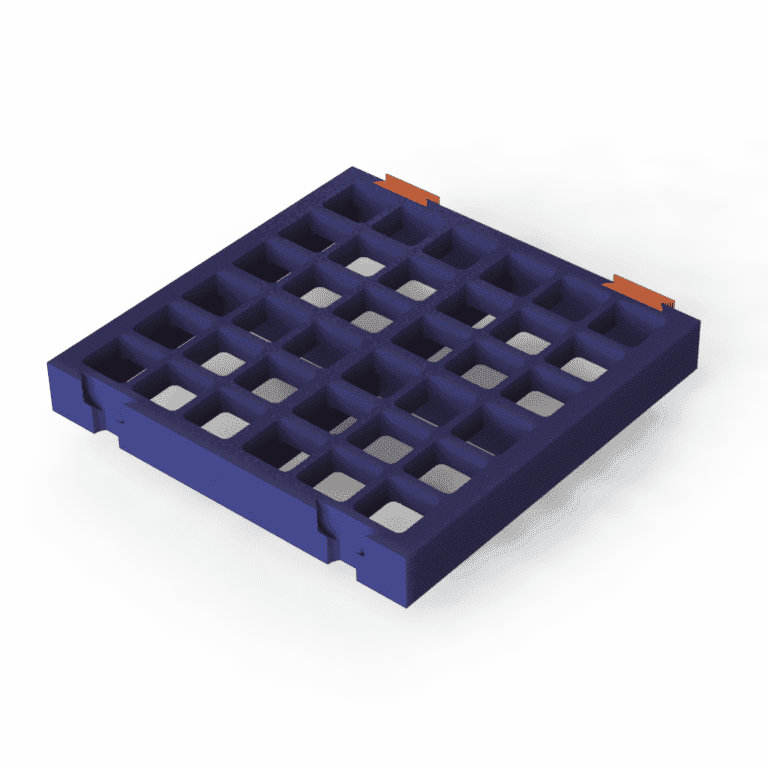

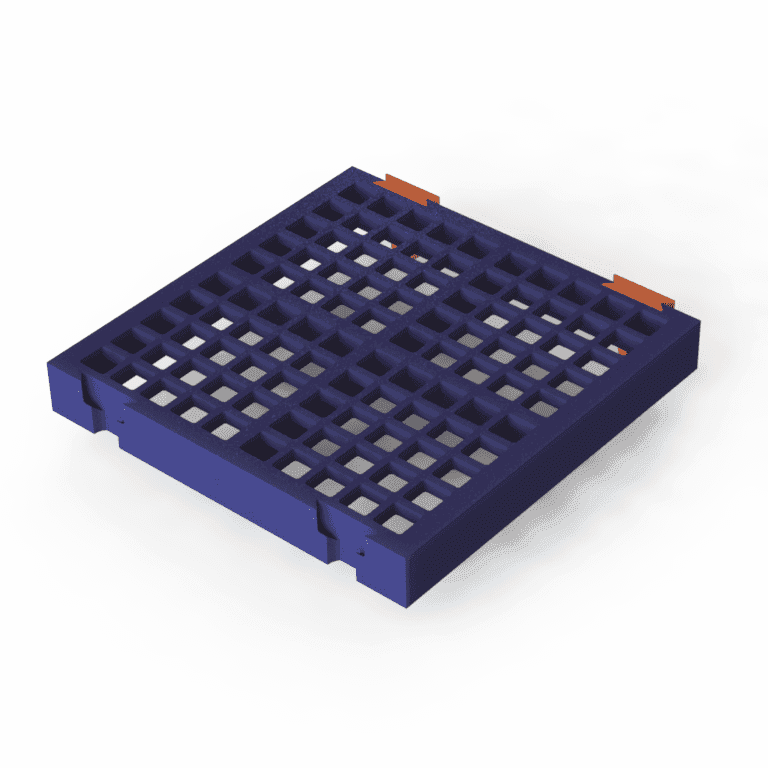

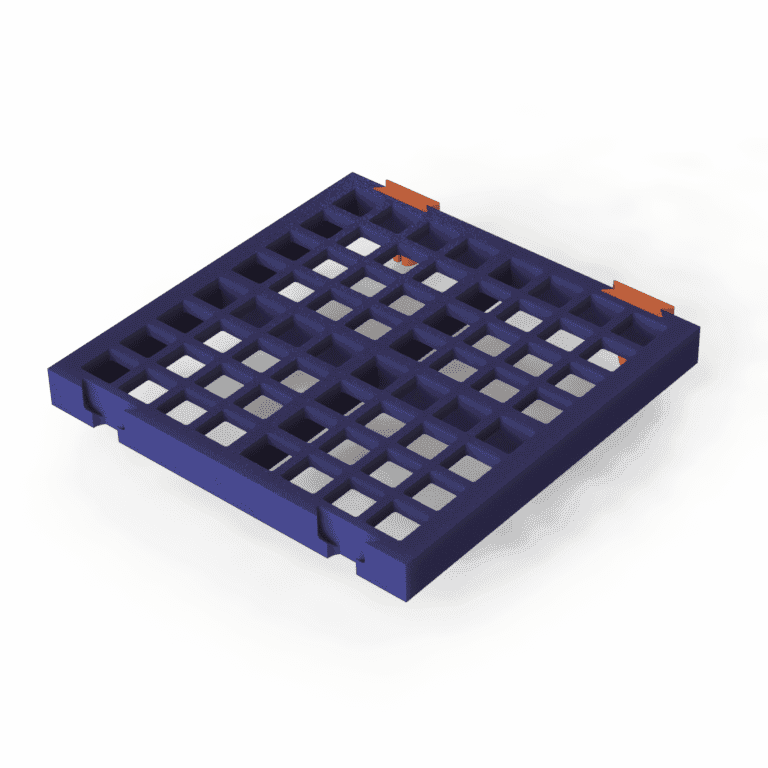

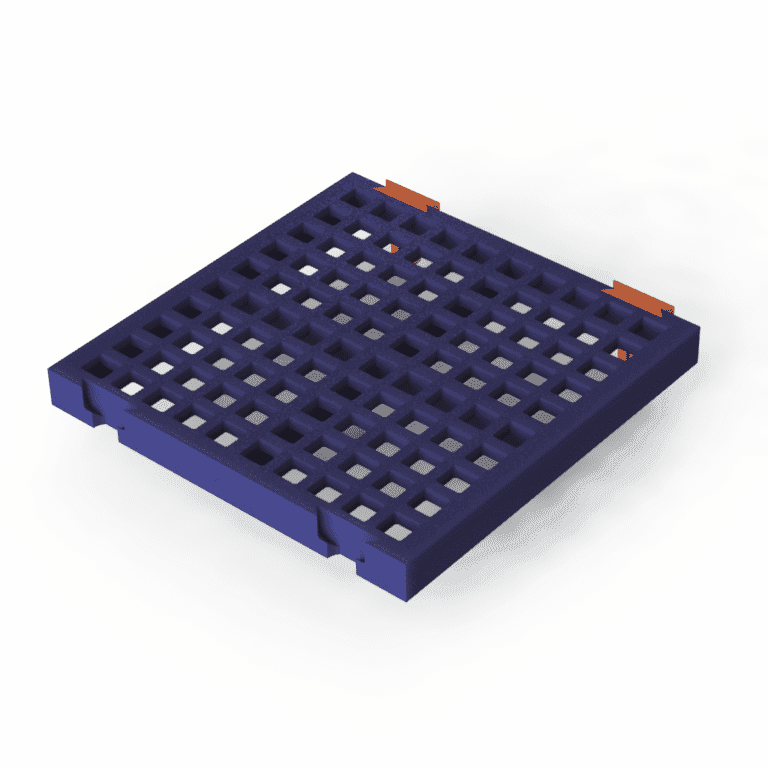

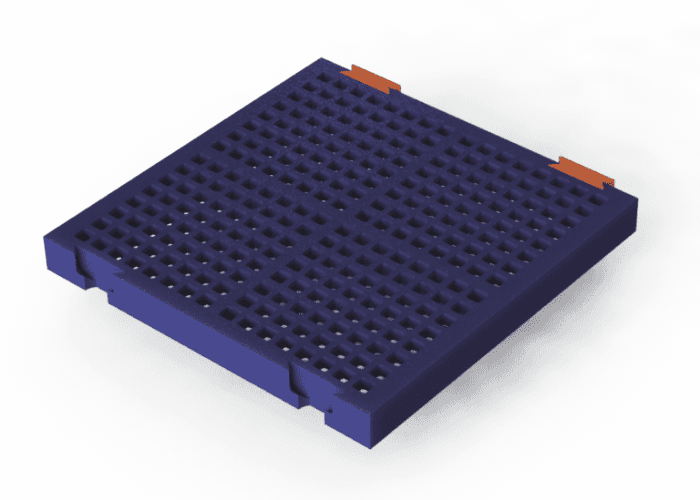

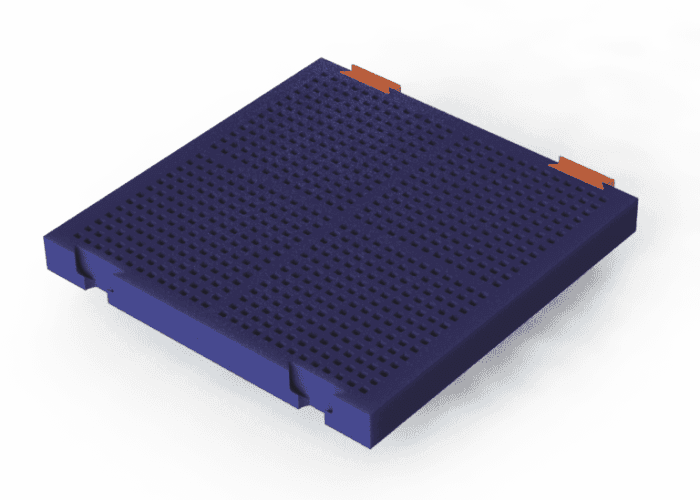

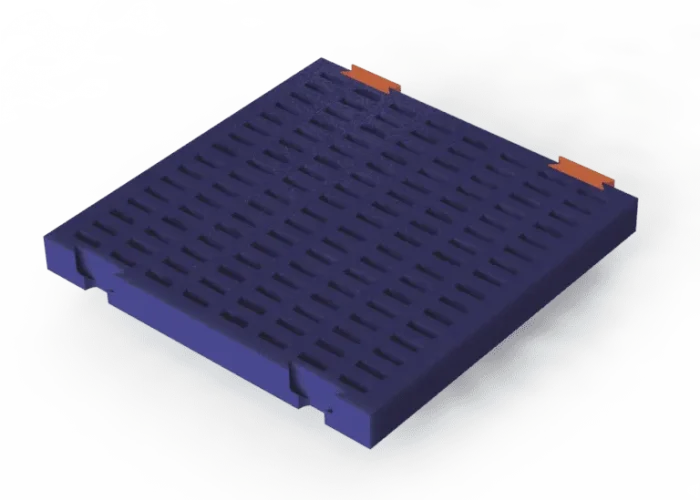

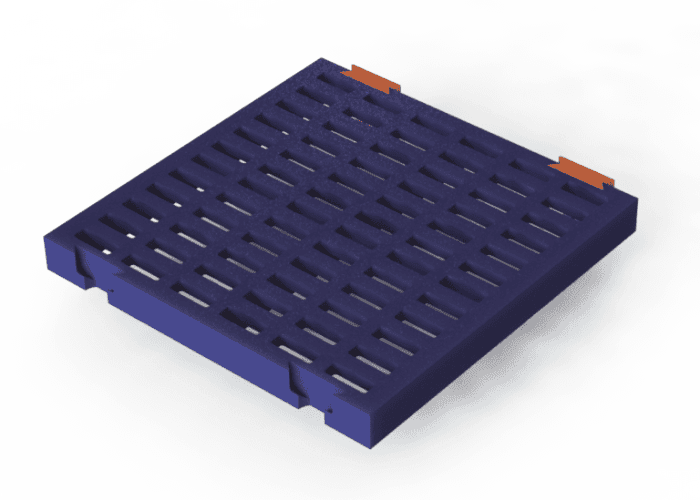

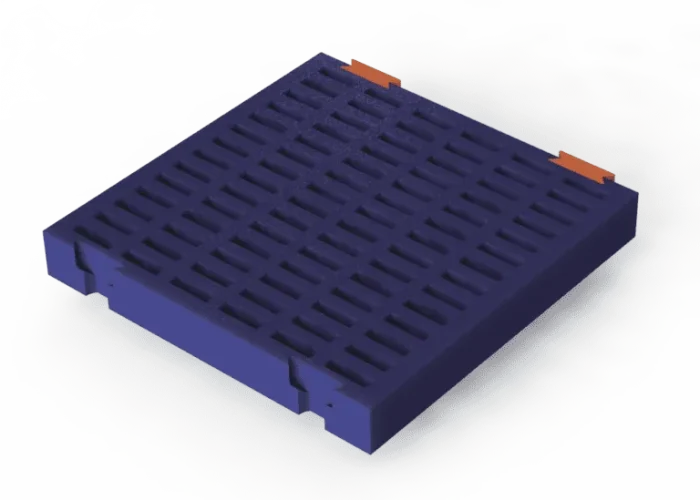

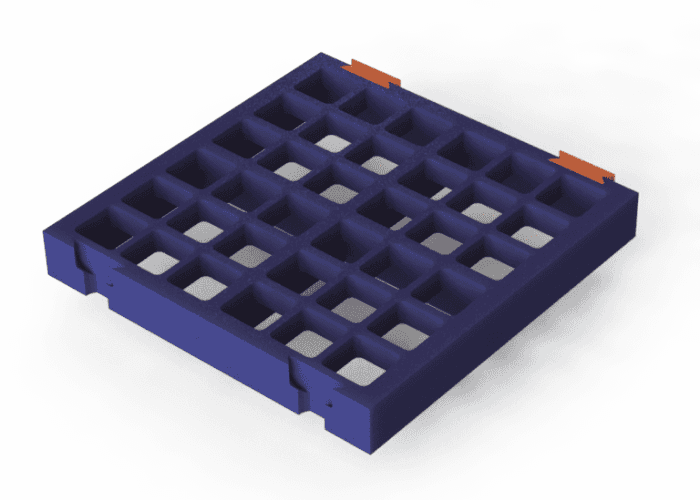

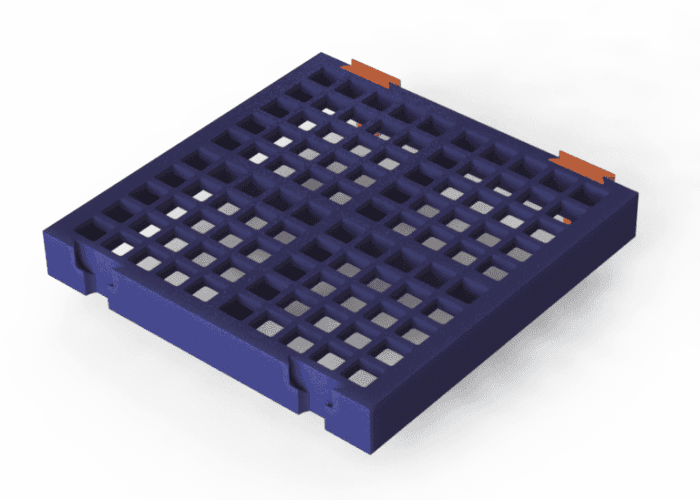

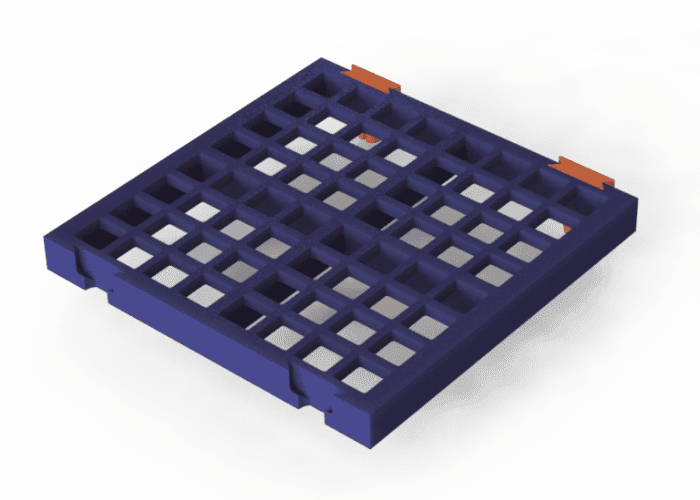

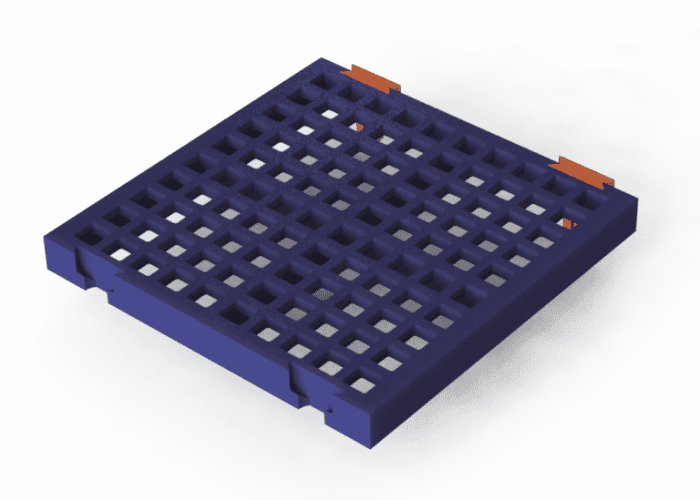

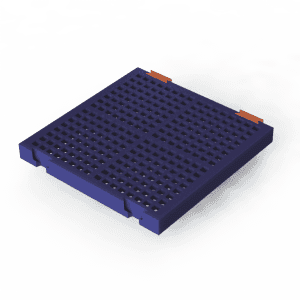

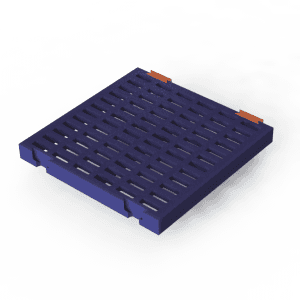

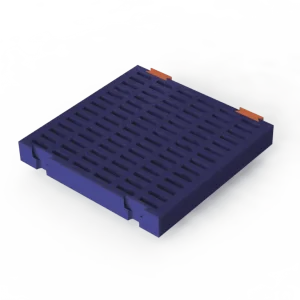

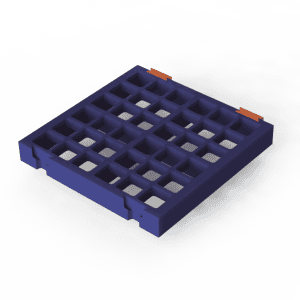

We have created a polyurethane screen panel with a patented V-type sleeve and pin fastening system that maximises the screening area, creating a screen panel with a higher open area. This, combined with the materials used in its manufacture, results in improved screening efficiency.

Polyurethane Screen Panels

Background overview

Screening is a crucial process in industries like mining, separating valuable materials from waste. It ensures that processed materials meet size and quality specifications and removes unwanted materials.

This process uses panels made of materials like wire mesh, polyurethane, rubber, and steel to allow desired particles to pass through while blocking others. Different panel types are available for specific applications, such as coarse or fine screening.

In mining, screening is used for various applications, including ore processing to separate valuable minerals from waste materials, scalping to remove larger, unwanted materials from the process stream, sizing to classify materials by size, and dewatering to remove moisture from the process stream in some mining applications.

When selecting screening media, it is essential to consider several factors, including:

Material type – The type of material being screened will dictate the type of screening media best suited for the application. For example, abrasive materials may require a more durable screen panel than softer materials.

Particle size – The desired particle size range will also impact the choice of screening media. For example, fine screening applications may require a panel with a smaller aperture size than coarse screening applications.

Operating conditions – The screening equipment’s operating conditions, including the frequency and amplitude of the vibration, will impact the selection of screening media. Panels that are too rigid or too flexible may not perform well under certain operating conditions.

Maintenance requirements – The ease of maintenance and replacement of the screening media should also be considered when selecting a panel. Panels that are difficult to replace or require frequent replacement may increase downtime and maintenance costs.

Polyurethane panels as the preferred material for screen panels

Monnark Polyurethane (PU) panels are often the preferred material for screen panels due to their many benefits, such as durability, versatility, and resistance to wear and tear. Our polyurethane screens are synthetic polymers that can be tailored to fit various applications, making them popular in a range of industries.

Advantages of using Monnark Polyurethane Screens:

Low maintenance: Monnark polyurethane screen panels require very little maintenance and can be easily cleaned with water and soap.

Extremely durable and able to withstand harsh weather conditions: Our polyurethane screens are perfect for outdoor applications in industries like mining, construction, and agriculture. They can also endure heat, cold, and moisture, which helps them maintain their structural integrity over time. Additionally, PU panels are lightweight, making them easier to transport and install compared to other materials.

Acoustic insulation properties: Our polyurethane screen panels can effectively reduce noise pollution, making them ideal for environments where noise levels need to be controlled. For instance, polyurethane screens are commonly used in recording studios, factories, and other areas where noise pollution is a concern.

Resistant to chemical corrosion: Our polyurethane screens are the ideal choice for applications where they may be exposed to chemicals or other substances. They are easy to clean, and their non-porous surface resists bacterial growth, making them perfect for use in areas where hygiene is critical, such as hospitals and food processing facilities.

Importance of higher open areas

Monnark screen panels have openings of different sizes to let specific particles pass through while retaining larger ones. It’s essential to use panels with higher open areas, because they provide:

Increased screening efficiency: Higher open areas in the Monnark screen panels increase screening efficiency by allowing more material to pass through. Low open areas restrict material flow, decreasing efficiency and making higher open areas beneficial, especially for materials with high moisture content.

Reduced maintenance: Screens with higher open areas require less maintenance as they are less prone to clogging and blinding. When the open area is low, the screen panels can easily become clogged with material, reducing the polyurethane screen’s efficiency and requiring frequent cleaning or replacement. With higher open areas, the material can pass through the screen panels more efficiently, reducing the need for maintenance and downtime.

Improved product quality: Increasing the open area of screens improves material quality by allowing smaller particles to pass through, resulting in a cleaner product.

Reduced energy consumption: High open area vibrating screens require less energy to operate. When the open area is low, material flow is restricted, requiring more energy to move the material through the screen. Higher open areas allow for easier material flow, reducing energy consumption and operating costs.

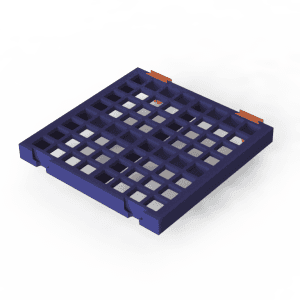

Aperture selection: Square or Slot apertures based on application

Vibrating screens are used in different industries to separate materials based on size or shape. The screen panels, featuring square or slotted apertures, play a crucial role in this process.

Square apertures are suited for materials of uniform size and shape, allowing for higher open area percentage and increased screening efficiency. On the other hand, slotted apertures are better for materials with varying sizes or containing fines, preventing clogging and reducing the need for frequent cleaning.

Slot aperture installations: Slot With Flow (SWF) vs Slot Into Pin (SIP)

In screen panel applications, slot apertures can be installed with the material flow for size classification and grading applications, or against the flow for dewatering and draining applications.

For example, slot apertures may be used in a gravel pit to separate stones from gravel with the material flow, or in a wastewater treatment plant to remove solids against the flow.

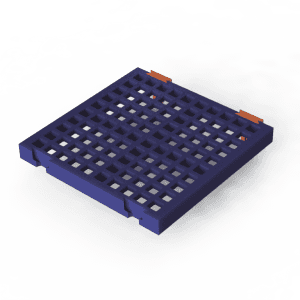

Standard polyurethane panel thickness (30 mm) vs thicker panel (40 mm)

Polyurethane screening panels, typically 30mm thick but available in 40mm, are used in vibrating screen applications for their durability and abrasion resistance.

Thicker panels are recommended for high wear rate, severe impact, and heavy load applications, such as in mining and quarrying. They can improve screen life and reduce maintenance costs. In less abrasive applications like sand and gravel operations, standard thickness panels may be more economical.

Design of apertures

The Monnark polyurethane screen panels have rounded corners in their apertures to prevent stress concentrations and improve the overall strength and durability of the panel.

The induced rounded corners distribute stress more evenly, reducing the likelihood of stress concentrations and improving strength. Additionally, they prevent material from getting caught, reducing clogging and improving screening efficiency.

In Conclusion

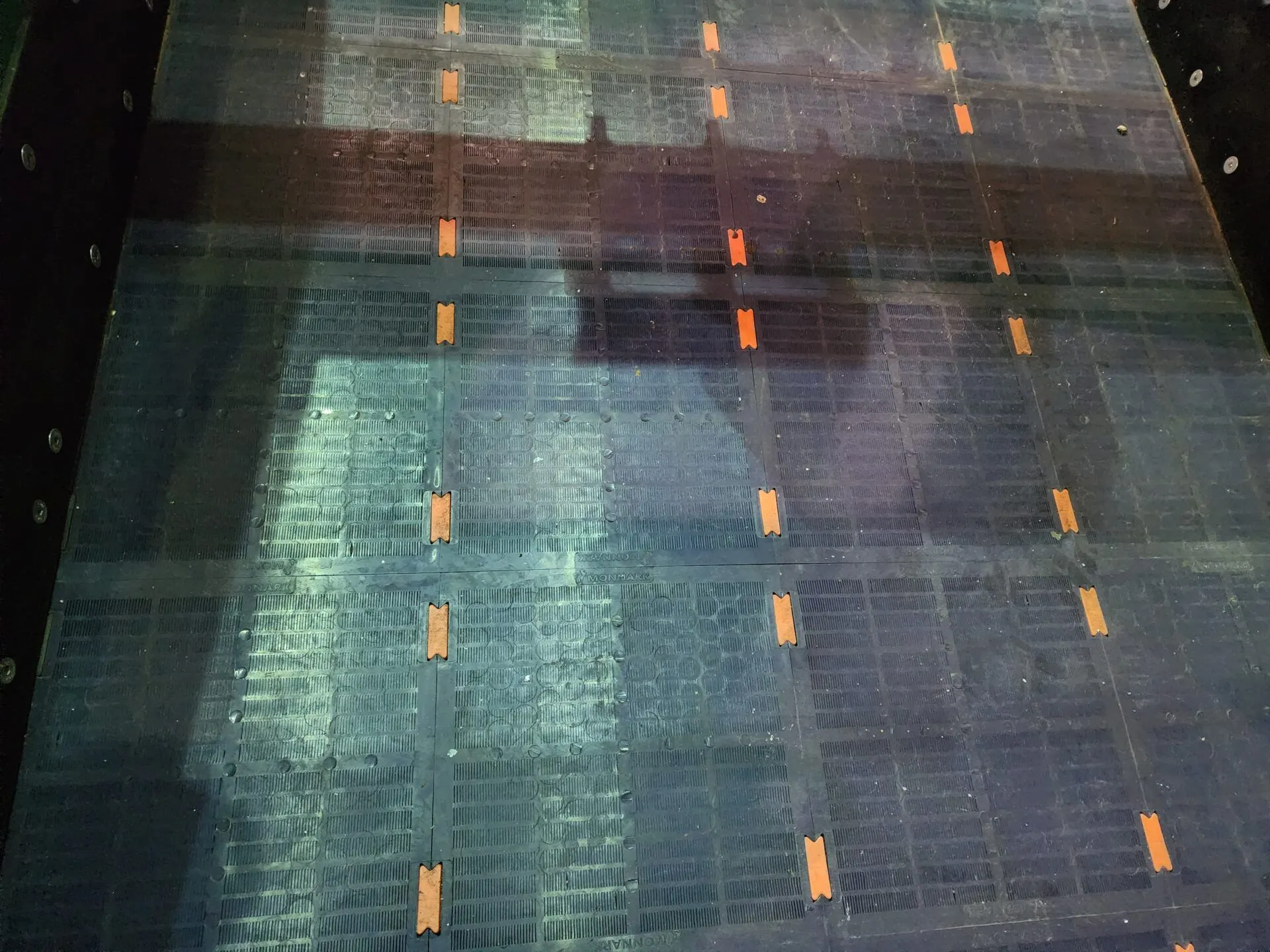

Mining processing plants are essential for the extraction of valuable minerals from the earth, making them a critical component of the mining industry. To ensure optimal performance and efficiency of these plants, the use of screening panels is a widely adopted practice.

Screening panels are designed to fit onto vibrating screens, with the primary objective of separating valuable minerals from waste materials during the mining process. Mines that uses Monnark panels benefit of using screening panels in various mining processing plant applications and commodities across Africa, especially advantageous to both engineers and mine owners.

One of the key benefits of screening panels is their ability to increase the productivity of mining processing plants. These panels are designed to efficiently separate minerals from waste materials, ensuring that only the valuable minerals are processed further. This results in a reduction in processing time and costs, allowing for more minerals to be extracted within a shorter time frame. The increased productivity also translates to increased profits for mine owners, making screening panels a crucial investment for any mining operation.

In addition to improving productivity, screening panels also help to reduce downtime and maintenance costs. By separating valuable minerals from waste materials, the panels reduce the wear and tear on other processing equipment, such as crushers and mills. This means that the equipment can operate for longer periods without requiring maintenance, reducing downtime and saving on maintenance costs.

Screening panels are also beneficial in improving the quality of the final product. By separating the valuable minerals from the waste materials, the panels ensure that the final product is of a higher quality, with fewer impurities. This is particularly important for mining operations where the quality of the final product is critical, such as in the production of high-grade iron ore or gold.

Another benefit of screening panels is their versatility in application across various mining processing plant commodities. The panels can be customized to suit the specific requirements of different commodities, such as coal, iron ore, gold, diamonds, and platinum. This means that mine owners can invest in a single screening panel that can be used across multiple commodities, reducing the need for multiple screening systems and lowering capital expenditure.

The use of screening panels also has environmental benefits. By separating valuable minerals from waste materials, the panels reduce the amount of waste material that is disposed of, thereby reducing the environmental impact of mining operations. The panels also help to reduce the amount of water and energy required for processing, further reducing the environmental impact of mining operations.

In conclusion, Monnark screening panels proves numerous benefits to mining processing plants across various commodities in Africa. They improve productivity, reduce downtime and maintenance costs, improve the quality of the final product, and have environmental benefits.

Furthermore, the versatility of screening panels means that they can be customized to suit the specific requirements of different commodities, reducing the need for multiple screening systems and lowering capital expenditure. Overall, the adoption of Monnark screening panels is a wise investment for any mining operation in Africa, benefiting both engineers and mine owners.

Monnark Mining

About us

Monnark Mining is a dynamic company with the advantage of using the latest technology in tooling design and techniques to enhance its product offering.

This allows the company to design tooling and products for the Mineral Processing industry to meet specific customer needs rather than improvise by utilising existing tooling.

The company team members have vast experience in the mineral processing industry, both in operations and through equipment supply in most mineral sectors.

Efficient and Durable Screen Panels

Usage Variety

Applications of Screening in the Mining Industry

Ore Processing – Screening separates the valuable minerals from the waste rock and other materials. This process is typically done in stages, with coarse screening followed by finer screening to achieve the desired particle size.

Scalping – This involves removing the larger, unwanted materials from the process stream before they enter the processing plant. Scalping screens are typically used in the primary stages of processing.

Sizing – Sizing screens classify materials by size and are commonly used in the final stages of processing to ensure that the final product meets the desired size specifications.

Dewatering – Dewatering screens remove water (or other liquid) from the process stream, which is essential in some mining applications.

Frequently Asked Questions

How does Monnark Mining prioritise innovation in equipment design?

At Monnark Mining, innovation is fundamental to our business. Our team of experienced engineers and designers stays updated on industry trends and technological advancements. Through research and expertise, we ensure our equipment meets the evolving needs of the mining industry with innovative features and solutions.

How does Monnark Mining’s equipment achieve technical efficiency?

Our equipment is designed and engineered to maximise technical efficiency. We use advanced engineering techniques and simulation tools to analyse and enhance performance, focusing on throughput, energy consumption, and maintenance needs to boost productivity and reduce downtime.

Can you explain the cost-effectiveness of Monnark Mining’s equipment?

In the mining industry, we prioritise cost-effectiveness in our equipment design. We use high-quality materials and innovative designs to ensure durability and low maintenance. Our solutions are tailored to optimise resource utilisation and reduce operating costs.

How does Monnark Mining maintain its position as a leader in the industry?

“Our company is committed to leading our industry by investing in research and development to stay ahead of technological advancements. Through active participation in industry conferences and collaboration with experts, we aim to influence best practices. Our focus on innovation, technical expertise, and customer satisfaction has allowed us to maintain our position as a recognised leader in the mining industry.”

What sets Monnark Mining apart from the competition?

Our company’s strong focus on innovation ensures that our equipment provides cutting-edge solutions. Our commitment to technical efficiency and cost-effectiveness, combined with our industry leadership, makes us the preferred choice in the mining industry.

Contact Us

We are a dynamic company utilizing cutting-edge technology in tooling design to deliver tailored solutions for the Mineral Processing industry.

+27 83 271 4477

Fernando.monteiro@monnark.co.za

Please complete the form below, and one of our specialists will provide the necessary help!